P&ID Conversion

Process data runs through the entire life cycle of the plant or equipment. With the open system architecture and consistent data platform, it can not only greatly save design time and human resources, reduce design costs, but also greatly improve design quality and reduce error rate. At the same time, it also ensures that from the factory design stage, asset management from the operation stage to the retirement or transformation stage, process data is not lost or inconsistent.

Process engineering data delivery: It can integrate all process data such as PFD, PID, various equipment tables, pipeline tables, and condition tables, such as COMOS FEED.

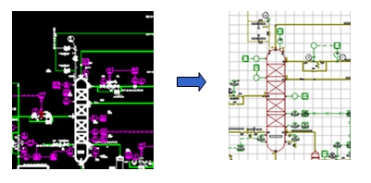

Intelligent P & ID Drawing Delivery: Whether P & ID drawings are based on traditional CAD or MicroStation systems or exist in paper form, we have high-quality personnel to provide high-quality and low-cost intelligent P & ID drawing conversion services, and to ensure strict control of documents and materials to ensure the safety and consistency of information. At present, intelligent P & ID software includes SmartPlant P & ID, AVEVA P & ID, AutoCAD Plant P & ID, COMOS P & ID, etc.

(Case Same as Process Engineering Design Service)

-

ꁸ Top

-

ꂅ +86-25-83206633

-

ꀥ QR code